Street Light Technical Information

|

|

Street Light Information Sheet - Understanding Early Arc Light Systems |

|

Prior to the invention of the Mazda type high output incandescent lamp, inventors struggled to design lamps that could produce consistent brilliant illumination. Oil, gas and early incandescent lamps had limited abilities to illuminate large areas. However for lighting larger areas, electricity was often relegated as a means to produce sparks to "automatically" light groups of gas lamps since the early carbon filament electric lamps were by today's standards pretty dim.

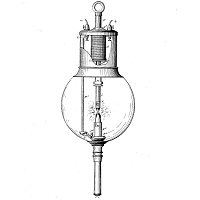

As far back as the early 1800s, inventors and researchers understood that bright light could be produced directly by electricity. In 1807 Sir Humphry Davy used a bank of 2,000 cells to generate a four inch arc of light between two charcoal sticks. While this experiment requiring a 2,000 cell battery did not produce a practical source of light, it did reveal that electricity could produce high intensity lighting if the details could be worked out.

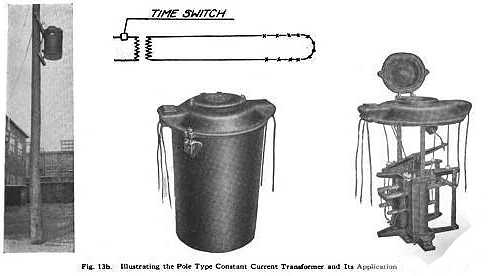

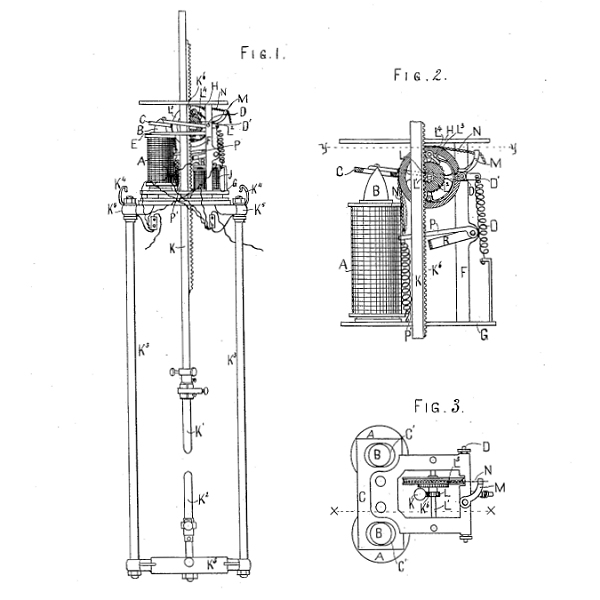

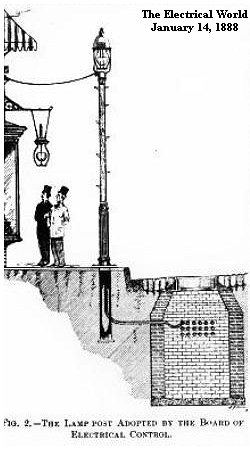

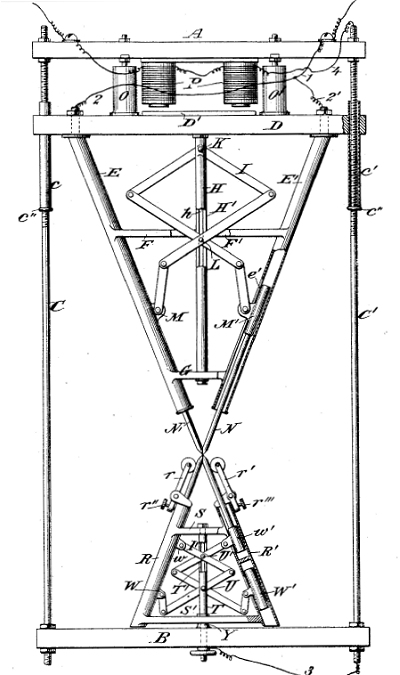

There were practical limits for producing a sustainable arc under varying outdoor conditions. A functional arc lamp operated at 80 volts or less, but consumed 6 or more amperes in current. Typical available line voltage was 120 or 240 volts. Line voltage had to be stepped down to properly supply the lamps. The arc was generated between two carbon electrodes known as rods or pencils. These electrodes would slowly be consumed as the lamp operated. The destruction of the tips of the electrodes required some mechanism to constantly adjust the electrodes in order to maintain the correct gap to sustain the arc. Regular cleaning and replacement of the electrodes was also necessary. With arc lamps that operated on direct current (DC,) only one electrode would be consumed when the lamp operated and DC arc lamps were less noisy. However DC lamps either required dedicated circuits or individual rectifiers in order to convert alternating current (AC) electrical service to DC. DC arc lamps were the brightest available, however they also consumed the most power. To address both the voltage and DC issues, most arc lamps operated in series on dedicated circuits supplied by a constant current DC regulator - transformer.

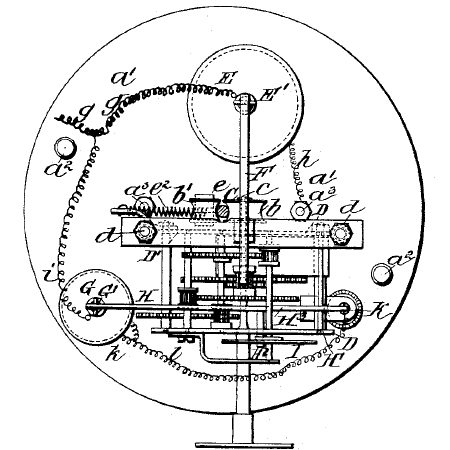

The regulator-transformer would continually adjust the voltage applied to the series circuit so that the current to each lamp was kept within a proper range. Series arc lamps also had to have isolation autotransformers or some kind of automatic cutout device so that if a lamp failed, the remaining lamps on the circuit would remain lit. (For a more detailed explanation how series circuits work, please visit Understanding Series Circuits.) One particular challenge involved correctly feeding the arc electrode in order to maintain the correct gap between it and the opposing electrode as it was being consumed. If the gap closed the lamp would short out. If the gap was too great, the arc would fail. Early carbon electrodes lasted about 74 hours, meaning that a little more than one-tenth of the electrode would be consumed each night. Inventors explored a number of different approaches. Some inventors tried clockwork mechanisms where hopefully the speed of the mechanism equaled the rate of consumption of the electrode. However electrode consumption could be affected by temperature, humidity, electrical fluctuations and other factors, so the clockwork devices had their issues.

To prevent the clockwork mechanism from closing the electrodes when it wasn't necessary, there was often a solenoid or similar device that was placed in series or in shunt with the electrodes. If the current across the electrodes varied past a specific threshold, the mechanism would then slowly lower the electrode into a more correct position. When the current across the electrodes returned to within normal limits, the mechanism would then stop moving. Another approach used a ratchet type system. Typically a high impedance magnetic coil was placed in shunt with the electrodes. When the arc started to fail and current across the electrode dropped, more current then traveled through the coil when then produced a magnetic attraction to a lever that closed the arc gap by a small amount. If the calibration was correct, the normal arc would resume and the ratchet lever would return to its unengaged position.

One problem associated with the ratchet type system was that if the arc did not stabilize when the ratchet actuated and the electrode moved, the current through the ratchet coil could remain high and the ratchet would be stuck in its actuated position until the circuit was turned off during the day. However the ratchet system seemed more immediately responsive to changes in the arc than the clockwork system.

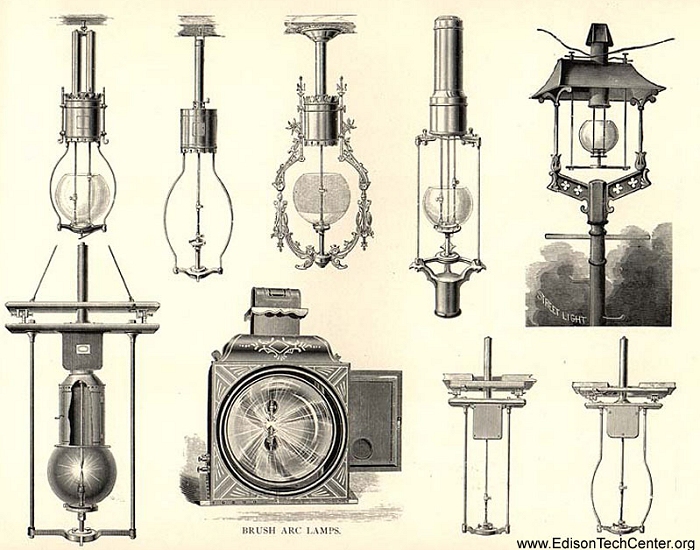

Inventors then experimented with duplex lamps having two pairs of rods where the second pair would take over if the first pair failed. Some tried weights associated with friction clutches where the rods would drop as needed when voltages fluctuated. Some inventors tried magnets. Some tried combinations of the various techniques. At least 100 designs were patented in an effort to make arc lamps more practical and their light output more steady. Arc lamps were also labor intensive. They required constant maintenance. The electrode rods had to be kept "trimmed." Ash from the consumed rods would collect in the bottom of the fixtures and have to be removed. At the time this amount of labor did not seem excessive since gas and oil lamps also required servicing. In addition, newer magnetite electrodes extended the average electrode life to 175 hours, but people were discovering that newly emerging types of incandescent electric lamps were going to be real labor and money savers. Another issue affecting the continued use of arc lamps was the noise that they produced. DC circuits helped reduce audible "buzz" but the arc itself generated interference with a new device that was gaining in popularity, the radio. While it wasn't of significant concern at the time, arc lamps gave off great quantities of ultraviolet light that could reach dangerous levels for people who had to be close by for long periods of time. The presence of ultraviolet light did excite certain phosphors to luminance and some inventors designed phosphor lined bowls that provided a more diffused source of light. As incandescent lamps became more powerful, the traditional arc lamp lost favor and disappeared. However the principals behind the basic carbon arc lamp became the basis for more modern neon, mercury vapor,fluorescent, sodium vapor, metal-halide and similar gaseous discharge lamps. To that extent the humble arc lamp actually contributed more to highway and outdoor lighting than the incandescent lamp. For more information on arc lamps please visit:

|

By the late 1870s relatively powerful electric generators were being developed. Russian engineer Paul Yablochkov designed a usable arc-producing device known then as the Yablochkov candle. His invention was used for street lighting in several European cities. It became evident that arc lamps were cheaper to operate and provided more light than gas or oil lamps, however the use of luminous arc lamps still had a number of complicating issues that engineers and inventors tried to overcome over the years.

By the late 1870s relatively powerful electric generators were being developed. Russian engineer Paul Yablochkov designed a usable arc-producing device known then as the Yablochkov candle. His invention was used for street lighting in several European cities. It became evident that arc lamps were cheaper to operate and provided more light than gas or oil lamps, however the use of luminous arc lamps still had a number of complicating issues that engineers and inventors tried to overcome over the years.

While arc lamps were far better than any other alternatives at the time, the light that they produced still fluctuated as the electrodes were consumed, then were automatically readjusted. Some models "winked" under certain conditions when the mechanisms did not keep up with rod consumption.

While arc lamps were far better than any other alternatives at the time, the light that they produced still fluctuated as the electrodes were consumed, then were automatically readjusted. Some models "winked" under certain conditions when the mechanisms did not keep up with rod consumption.